Joanne

4/1/2025 1:56:57 PM

3 mins read

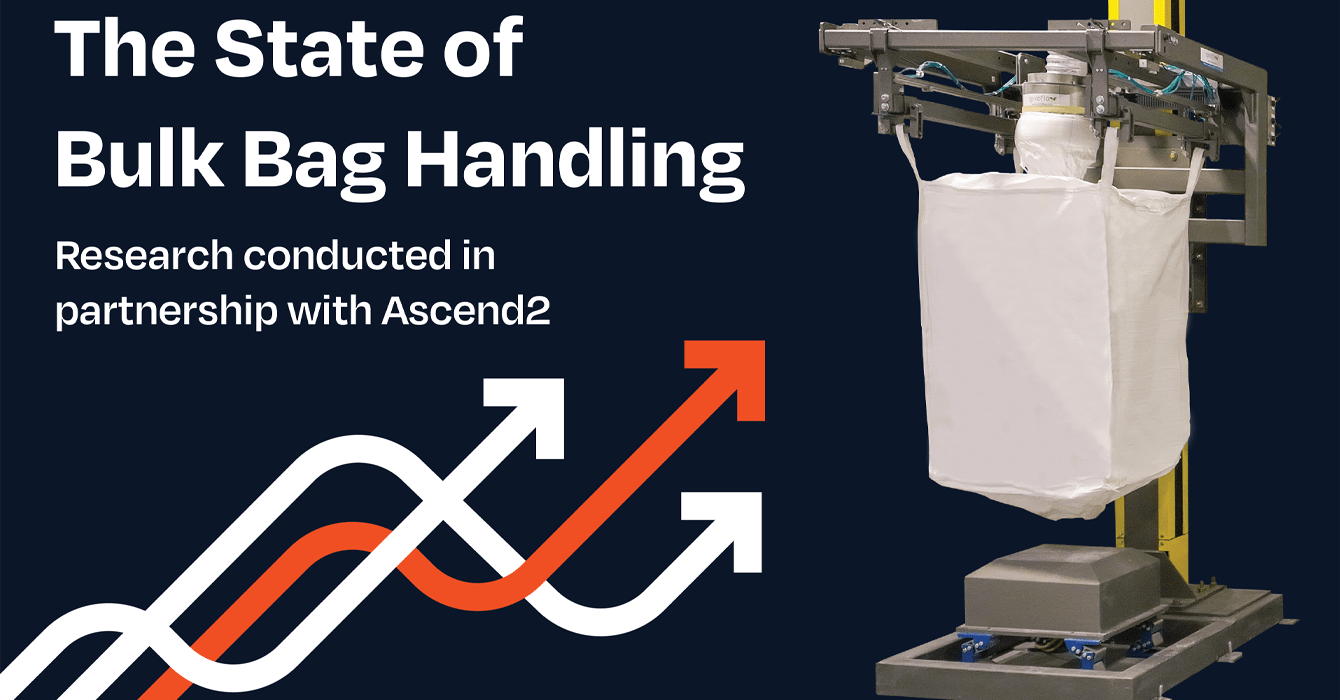

Global powder handling and dry bulk solids processing specialist Spiroflow, an Akona Process Solutions company, has published its 2024 State of Bulk Bag Handling report, providing key insights into industry trends and future investment plans. The findings indicate a positive outlook, with 77% of industry professionals contemplating upgrades or replacements for bulk bag handling equipment within the next two years. The report also demonstrates strong business growth, with nearly all respondents (98%) reporting an increase in activity over the past year and more than half (52%) experiencing growth rates exceeding 11%.

Efficiency continues to be a key focus for the industry, with 44% of respondents seeking to enhance operational performance through equipment upgrades. Modern bulk bag systems allow companies to maximise loads, particularly for materials with bulk densities under 30 lb/ft³, resulting in significant cost savings in transportation and storage. Additionally, 42% of industry professionals seek to minimise downtime by investing in newer equipment for easier maintenance and quicker part replacements. This ensures continuous operation and extends equipment lifespan.

Workplace ergonomics is another critical concern, with 31% of respondents focused on improving operator safety and comfort. Upgraded bulk bag handling systems reduce manual handling, bending, and stretching, mitigating common risks associated with material handling.

In response to these industry trends, Spiroflow continues to develop innovative solutions tailored to evolving customer needs. For instance, the Cone Table Elite (CTE) Bulk Bag Filler is designed to exceed industry performance standards by filling over 40 bags per hour, compared to the conventional 20 bags. This system offers a weighing accuracy of +/- 1-2 lbs and employs advanced densification technology, allowing for up to 25% more product per bag. These features enhance operational efficiency and significantly reduce shipping costs by optimising container and truck utilisation. Additionally, Spiroflow has introduced a new sack tip station that improves air quality and material handling efficiency, addressing common workplace challenges associated with bulk bag handling.

With facilities in the UK, Germany and the US, Spiroflow delivers innovative solutions that enhance operational efficiency and safety. The company designs and manufactures bespoke material handling equipment and automated handling solutions principally for the food and beverage, pharmaceuticals, chemicals and energy industries.

To download the full report click here.