Joanne

9/16/2025 3:18:41 PM

4 mins read

Across Europe, particularly in countries such as the Netherlands, Belgium and the UK, the food and beverage industry is under increasing pressure to reduce its carbon emissions. Ambitious national climate targets, rising energy prices and growing consumer preference for sustainable products are driving manufacturers to shift away from fossil fuels. However, this presents a challenge as most industrial food processes are heat-intensive and still predominantly powered by gas or oil.

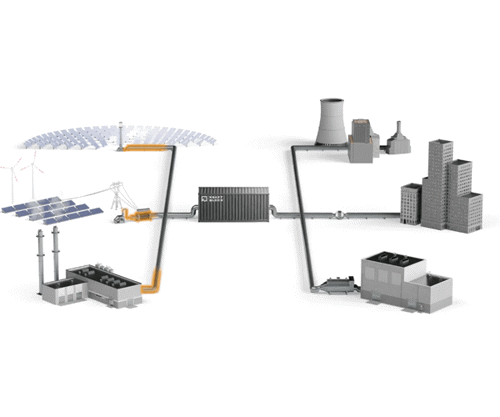

Electrification today is not only easy but can be made very cost-effective. The key to achieving low energy prices for process heat is thermal energy storage systems (TES) powered by renewable electricity. These systems reliably and efficiently deliver high-temperature heat and provide energy flexibility to industrial users and the broader electricity grid.

By storing energy when electricity prices are low — or even negative due to renewable energy surplus — and using it during periods of high demand, industries can avoid high peak costs, stabilize operations and reduce emissions. This type of load shifting is important in today's energy landscape as grid congestion and price volatility present obstacles in cleaner grids. Grid congestion in the Netherlands, for instance, is estimated to cost between €10 and €40 billion per year.

How thermal energy storage (TES) works

The electricity taken from low-price times is transformed to heat, usually by a resistive heater with an efficiency of around 99%. This heat is transferred through the storage material. In Krafblock’s case, a blower blows the heat into the storage. Here, the specifically developed, upcycled material, heats up. The insulated storage container can hold the heat for hours to days and can store as high as 1,300°C. This enables to store a large amount of energy in a small space.

When the energy is needed or around the clock, the storage is discharged: Ambient air is blown into the container and heats up from the Kraftblock material. Then it is transported directly to the customer at the right temperature or a heat exchanger or a steam boiler allows to change the heat carrier to steam, thermal oil, water or inert gases.

This concept is already being implemented by PepsiCo and Eneco in the Netherlands through the Volt Project, replacing a 25 MW gas-fired boiler with Kraftblock’s thermal energy storage. It will decarbonize the frying process for potato chips, cutting over 98% of site emissions and saving thousands of tones of CO₂ annually.

To demonstrate the potential of thermal energy storage for the food industry, it is helpful to examine how this technology could contribute to achieving net zero in sectors such as brewing, coffee production and oilseed processing. These sectors have different heat requirements, ranging from steam-based brewing and hot-air roasting to hot deodorisation.

Breweries: A steam-driven sector ready for electrification

Breweries consume large volumes of energy, particularly as 60–75% of that demand is for process heat which is used in mashing, lautering, wort boiling, pasteurization, and sterilization. In the Netherlands, over 25 million hectoliters of beer are brewed annually. Heineken, with global production exceeding the U.S., likely has an annual energy demand of roughly 9,700 GWh, possibly lower due to advanced efficiency measures. Anheuser-Busch InBev, the world’s largest brewer, produced over 500 million hectoliters in 2023, with a potential demand of up to 19 TWh per year.

This heat is typically supplied by centralized steam networks at 175–195 °C. Direct replacement of these systems with electric steam boilers is technically possible, but not economically viable without load flexibility, due to the volatility of electricity prices.

Thermal storage solutions allow renewable electricity to be stored as high-temperature heat and dispatched as steam exactly when needed. By charging the system when electricity is cheapest, such as during midday solar peaks or overnight wind generation, breweries can significantly reduce their operational costs (OPEX) while reducing CO₂ emissions, and hence, reducing the dependency on fossil fuels.

Coffee: Roasting and drying without carbon emissions

Coffee is the world’s second most consumed beverage after water. Europe is a key hub in both consumption and processing, with the UK alone importing over 140,000 tones of green coffee beans annually.

The most energy-intensive process in coffee production is roasting, which occurs at 150–250 °C using hot air or direct flame. Follow-up steps like spray drying for instant coffee production also demands high temperatures (160–185 °C).

Instead of fossil fuels, roasters can now rely on heat generated from renewable electricity, stored and supplied when needed. For facilities already using indirect hot air roasting systems, the integration is seamless, no overhaul of existing infrastructure is required as systems like Kraftblock can supply heat in many forms and work directly on hot air.

This approach also aligns with life-cycle assessments as roasting and drying are key contributors to coffee’s carbon footprint. Electrifying these processes can help brands meet sustainability targets, appeal to eco-conscious consumers, and reduce energy costs.

Oilseed processing: Tackling solvent removal and odor neutralization

The oilseed industry, which includes the processing of rapeseed, sunflower and soybeans, also benefits from thermal energy storage. Two stages stand out in the heat network of the factories:

Desolventizing: Following oil extraction via solvent methods, heat is applied to evaporate and remove hexane, a volatile compound used in the process. This typically requires steam at 105–120 °C.

Deodorization: A refining step to neutralize odors, performed at temperatures exceeding 200 °C, often using high-pressure steam or thermal oil systems.

Thermal storage systems can deliver controlled heat input for sensitive desolventizing operations, as well as high-grade heat for deodorization. The system allows for load shifting, meaning operators can avoid peak power prices and benefit from surplus renewable energy in the grid.

Moreover, this transition supports compliance with tightening environmental regulations on solvent emissions and carbon intensity — particularly relevant in the Netherlands and UK, where climate policies are rapidly evolving.

The numerous advantages of Kraftblock’s thermal storage solution

Thermal energy storage systems offer numerous benefits for the decarbonisation of industry. They enable load flexibility, allowing manufacturers to use electricity at the cheapest times, such as during periods of high solar or wind generation, thereby significantly reducing energy costs. Designed for system compatibility, the technology can be easily retrofitted into existing steam or air-based heat infrastructure without requiring a complete overhaul of the system. With high thermal output and a modular design, the systems are scalable for medium to large industrial operations. These systems deliver substantial cost savings, particularly in markets with rising carbon prices, by reducing operational expenditure (OPEX) compared to fossil fuel-powered boilers. Most importantly, they enable near-zero emissions when powered by renewable electricity. From a regulatory perspective, this approach aligns with major European policy incentives and is specifically mentioned in the upcoming Industrial Decarbonization Bank.

Whether it’s a brewery, a coffee roaster, or an oilseed refinery, one thing is clear: the transition away from fossil-based heat is not only necessary, but also technically feasible and economically attractive. With technologies like Kraftblock’s thermal energy storage, manufacturers can preserve the integrity of their processes while unlocking energy savings and achieving climate goals.

In the Netherlands the project with Eneco and PepsiCo to decarbonize a snack plant with Kraftblock’s thermal energy storage system.

This project is supported by the German Federal Ministry for Economic Affairs and Energy as part of the Renewable Energy Solutions Programme of the German Energy Solutions Initiative.