Kim

7/2/2024 11:25:47 AM

4 mins read

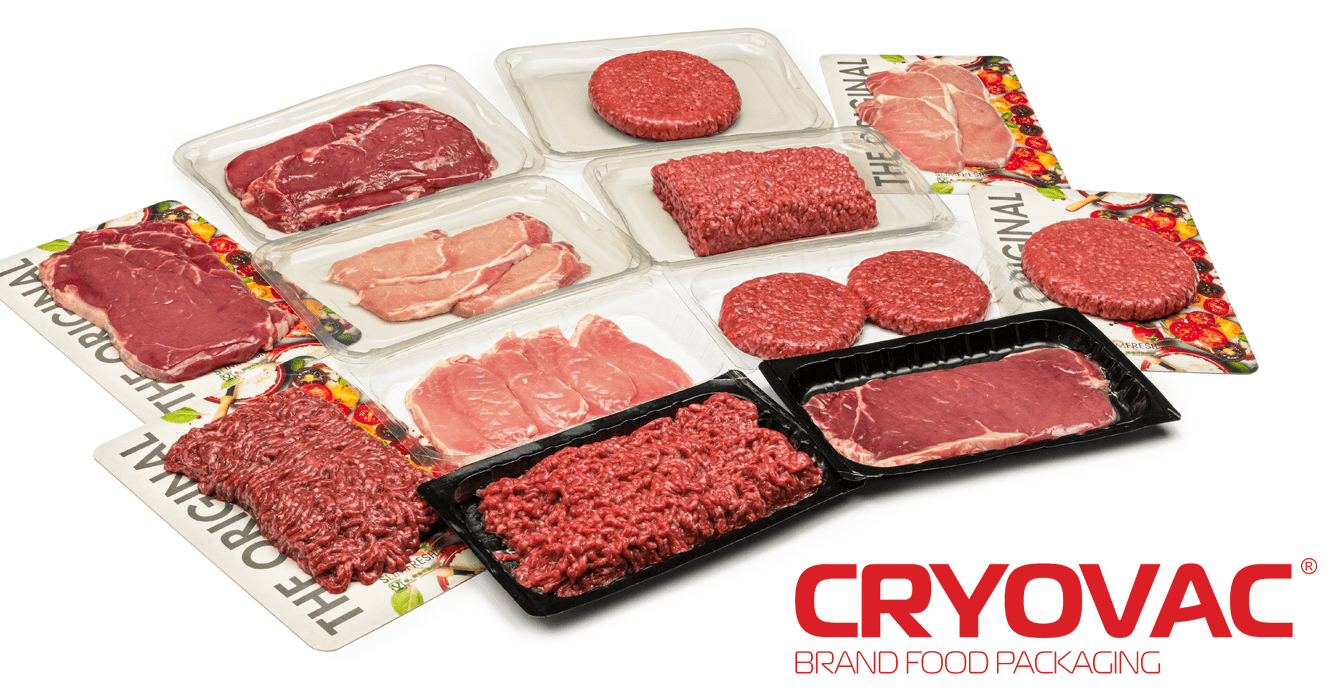

SEE, a pioneer in packaging innovation and sustainability, is excited to announce the launch of three groundbreaking skin packaging top webs designed to set new standards in packaging efficiency and performance. The introduction of these high-performance, cost-effective solutions marks a significant milestone in SEE’s commitment to revolutionising the packaging industry.

Compatible with the company’s renowned CRYOVAC® Darfresh® on Tray, Darfresh rollstock, and Vacuum Tray Skin technologies, the new top webs are engineered to offer unparalleled benefits to food processors. Key features include a superior oxygen barrier, enhanced optical properties, exceptional formability, and robust implosion resistance and sealability. Importantly, these advancements come without compromising the shape or integrity of the packaged products.

The innovative design of the top webs enables a notable reduction in total packaging cost (TOPACO) with Darfresh® on Tray system by 15-53% versus Modified Atmosphere Packaging (MAP), depending on the tray thickness. This efficiency gain is a testament to SEE’s dedication to delivering cost-effective solutions without sacrificing quality.

The new top web facilitates a significant downgauging from the traditional 100/120 microns to 80 microns for all the skin systems. For applications utilizing the Darfresh® on Tray technology, this reduction not only decreases material usage but also results in a 21-37% reduction in carbon footprint compared to MAP, thanks to diminished food waste and tray thickness. The upgrade also boosts productivity, increasing from 6 cycles per minute to 8.5 cycles per minute, providing food processors with enhanced operational efficiency.

When paired with Vacuum Tray Skin technology, the new top webs achieve a remarkable 4-51% plastic reduction compared to other tray skin materials available on the market, allowing tray thickness downgauging, further underscoring SEE’s leadership in sustainable packaging solutions.

“SEE is proud to introduce these revolutionary skin packaging solutions to the market,” said Marta Lara, Senior Marketing Manager, Food Retail, EMEA at SEE. “Our commitment to innovation, sustainability, and customer success is reflected in these new offerings. We believe that these enhancements will not only benefit our clients by improving efficiency and reducing costs but also contribute significantly to our shared goal of a more sustainable future.”

SEE continues to lead the way in providing sustainable, high-performance packaging solutions that meet the evolving needs of industries worldwide. With the launch of its new skin packaging top webs, SEE reaffirms its dedication to protecting goods, preserving food, and enhancing business operations through innovative and responsible packaging solutions.