11/6/2024 2:01:17 PM

-7 min read

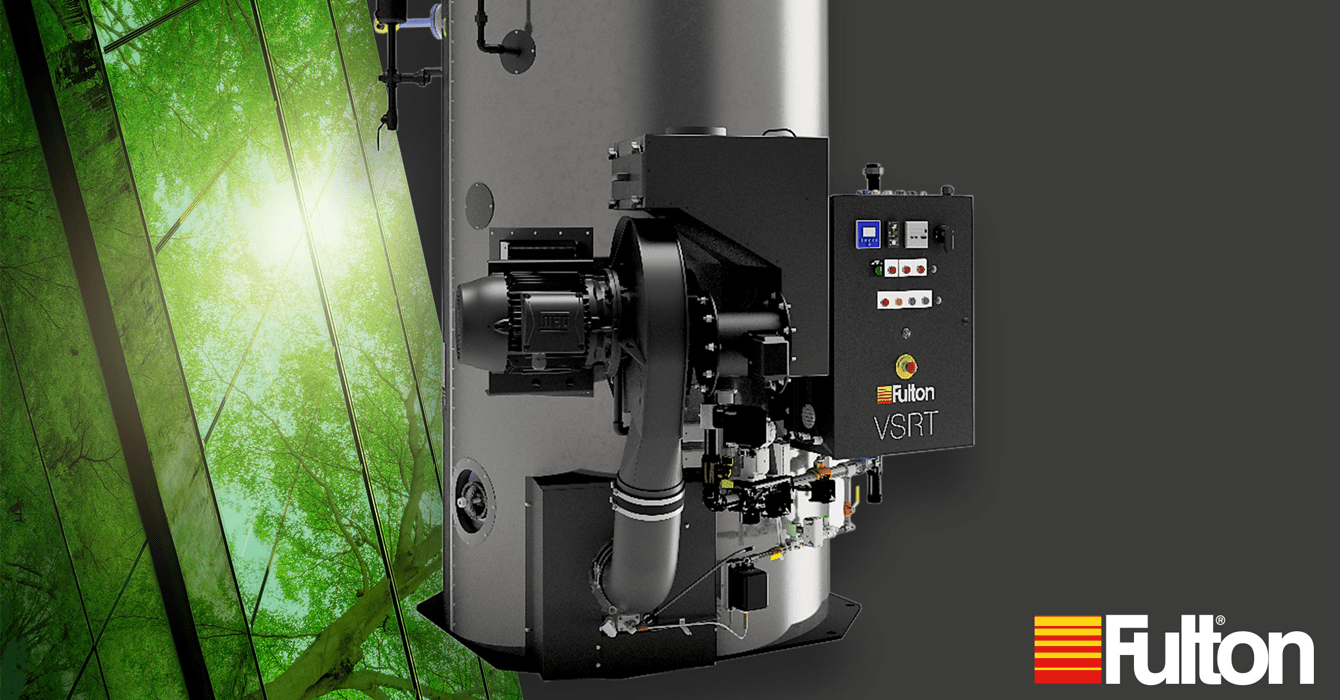

With the two types often being confused, Carl Knight, managing director of heat transfer specialist Fulton Limited, discusses the differences between shell type fired steam boilers and steam generators.

The objectives of a steam raising plant are simple: to release the energy in the input fuel as efficiently as possible; to transfer the released energy to the water and raise steam by the most efficient method possible; separating the steam from the water ready for export to the plant, where the steam energy (heat) can be transferred to the process.

Steam generators operate with low water content, pumping water into a continuously wound steel tube (coil) where steam and water are produced. These coils are housed in an insulated jacket with a burner typically firing from the top down, allowing hot flue gases to circulate around the coils. Due to their design, steam generators cannot produce steam when the burner is off and are not suitable for fluctuating steam loads. However, they can quickly reach operational pressure from a cold start, although a purging cycle before firing can delay steam availability.

In contrast, shell-type steam boilers, like Fulton’s VSRT, are constructed as pressure vessels with a larger water volume that can generate flash steam even when the burner is off. This design allows them to respond effectively to varying steam demands, making them more versatile despite longer cold start times. Additionally, they achieve rapid burner firing without the need for a water purging cycle.

Steam generators face challenges in matching burner output with steam requirements, often leading to excess feedwater that must be recirculated. This can possibly increase maintenance costs arising from premature pump failure which, due to their complex nature, require skilled technical support. Conversely, steam boilers utilise multistage centrifugal pumps that are far easier to maintain.

To ensure dryer steam from generators, an advanced steam separator is used to remove excess water, which is often sent to drain. High total dissolved solids (TDS) in separated water can lead to additional costs if disposal is necessary. Ineffective separation may allow TDS water droplets into the steam system, impacting process efficiency. A critical issue for generators is that phase changes from water to steam occur over the same coil length, where hard mineral deposits accumulate and potentially overheat/block the coils. Stringent water treatment and evacuation are essential to prevent costly coil replacements.

Shell type boilers also require TDS control; managing TDS through automated blowdown systems that prevent high TDS building in the boiler and entering the steam system. While feedwater quality control is crucial for both systems, it is less stringent for boilers due to their robust design and versatility, with their simpler control systems allowing for quicker easier repairs.

Provided shell type boilers are maintained properly, minimum life expectancy is 15 to 20 years, with Fulton regularly servicing and maintaining boilers that have been operating for 25 years or more.

In summary, while both steam generators and shell-type boilers serve similar purposes in energy production through steam, their designs cater to different operational needs. Steam generators excel in quick startups and compactness but struggle with variable loads and require careful management of feedwater quality. Shell boilers offer greater flexibility in handling fluctuating demands due to their larger water volume and robust construction but do have marginally longer startup times. Understanding these differences is crucial for selecting the appropriate system based on specific operational or process requirements.

For further information on the VSRT, call Fulton on 0117 972 3322, email sales@fulton.co.uk or visit www.fulton.co.uk.